|

||||||||

| March 15, 2017 | ||||||||

| BFB boiler at Heinola plus Preventing Dissolving Tank Explosion webinar |  |

|||||||

|

· Subscribe to Ahead of the Curve · Newsletters · Ahead of the Curve archived issues · Contact the Editor

|

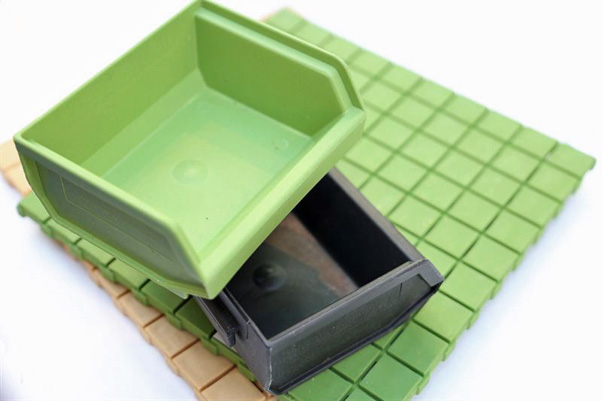

Side-stream, byproduct – or revenue source? “One person’s trash is another person’s treasure,” the saying goes. Yet this need not only apply to resale store bargains and attic discoveries. For pulp and paper companies, the concept of finding value in process by-products can mean large-scale gains. These additional revenue sources are a boon in a highly competitive global market, and are sparking the development of innovations that boost sustainability as well as the bottom line. Re-use of unwanted byproducts and materials is nothing new for pulp and papermakers. Yet we’ve rounded up a few particularly interesting new products being developed that find value in surprising materials. Plastec Finland Oy and Wiitta Oy produced a trial batch of floor tiles and storage containers made of plastic composites; paper and board industry side-streams accounted for 30 percent of the material. Photo: VTT. Sludge and Fly Ash into Plastics Large quantities of various side streams are created during the manufacture of paper and cardboard. Part of these can be used instead of natural aggregates as a raw material in concrete or asphalt, or in construction. Yet large amounts of side streams still end up in landfills and incineration. Side streams could be used to lower composite manufacturing costs, reduce the environmental impacts of production, and lower the total amount of waste. This would also reduce the production of oil-based plastics. Laboratory tests showed that 50 percent of the raw materials in injection-molded composite could come from paper and board industry side streams. The amount of side streams has an effect on the product’s properties—strength, stiffness, heat resistance, appearance, and the texture of the surface. During the project, Plastec Finland Oy and Wiitta Oy produced floor tiles and storage containers with a side-streams content of 30 percent. Researchers are continually exploring new applications; in the future, they may include pallets and crates, for example. Lignin into Glue As reported by Anna Ringstrom for Reuters, many Nordic-based forest firms such as Stora Enso, UPM-Kymmene, Metsa Group, SCA, and Holmen are working to find profitable uses for by-products that mills have previously burned for power. “Firms racing to replace paper business lost to the internet are trying to transform their pulp mill by-products into glue, biofuel and carbon fiber for aircraft and wind turbines,” she writes. Developments in more energy-efficient pulp mills, as well as growing global demand for fossil-free materials, are supporting these efforts. In her report, Ringstrom quotes Sasja Beslik, head of sustainable finance at Nordea, one of the Nordic region’s biggest asset managers and Stora Enso’s seventh largest shareholder. “If they can develop new materials to replace fossil based materials, the market is endless for them,” Beslik says. Stora Enso’s research with kraft lignin has pointed to early success. When the company opened its new kraft lignin plant in 2015, they chose to focus on using lignin to replace petroleum-derived phenols in glue. Ringstrom reports that Stora Enso’s kraft lignin plant, which is integrated with its Sunila pulp mill in Finland, has capacity to produce around 50,000 metric tons a year of refined kraft lignin. By the end of 2016, the company had signed its first order. “We’re now in business with a glue maker and deliveries are already ongoing,” CEO Karl-Henrik Sundstrom told Reuters. Microorganisms into Fish Food “There is a growing interest from the fish farming industry to develop fish feed with less environmental impact and resource competition compared with current products,” said Sara Hornborg, RISE Bioscience and materials, researcher and project leader for SALMONAID. “It is of outmost importance to reduce the dependence on fish meal and fish oil in feed to fish, not least in order to have balanced ecosystems in the oceans. Soy, which so far has been used more and more as a substitute, is also being questioned. This is why microbes using residual streams from the Swedish forest industry is a very interesting raw material.”

Key to the project are two multi-bioreactor systems that will use spent sulfite liquor from Domsjö Fabriker, a leading Swedish specialty pulp and bio-refinery company, as a raw material; with the aid of microorganisms, the systems will produce protein and oil for fish feed. “The cultivation trials will be performed under different conditions to optimize the process for production of a high-quality protein product. When we have found the prerequisites for a high quality product, we will successively produce increasing amounts in our bioreactors. At the end of the project period, our aim is to be able to produce high quality single cell protein that works well in fish feed and which in turn gives good results in feeding of fish.” said Björn Alriksson, biotechnology manager, Processum. For a modest investment of $174, receive more than US$ 1000 in benefits in return. |

|||||||

|

||||||||