|

||||||||

| September 27, 2017 | ||||||||

| Earning your trust every day - Valmet Field Services |  |

|||||||

|

· Subscribe to Ahead of the Curve · Newsletters · Ahead of the Curve archived issues · Contact the Editor

|

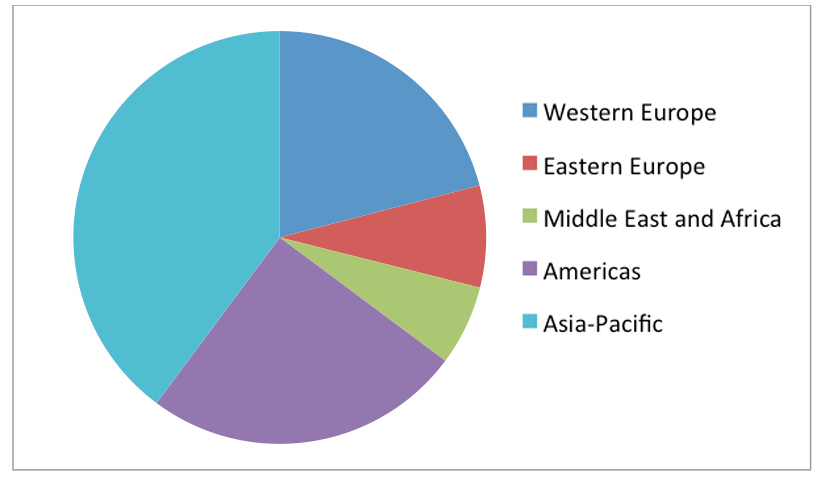

Four technologies poised to disrupt the specialty paper market In its latest research, Smithers Pira has identified four novel technologies that are set to increase capacity and enable new product opportunities for manufacturers of specialty papers across the next five years. The new report—The Future of Speciality Papers to 2022—provides a comprehensive overview of this important sector of the paper industry. It incorporates both higher volume applications, like flexible packaging and label stocks, and more niche segments like electrical insulation, filtration, and security papers. Smithers Pira’s analysis charts how global consumption of speciality papers in 2017 has reached 24.16 million metric tons. Steady growth will continue through the end of the decade at 2.2 percent per year, to push this figure to 26.98 million metric tons in 2022. US perspective The plummet in printing and writing paper demand linked to the emergence of the Internet began in the US, and it continues to reshape the papermaking landscape. Speciality papers have become attractive for stranded assets that are new and can be economically refocused—filtration and battery insulator papers in particular are showing good resilience in the face of the broader industry competition with polymer alternatives. Simultaneously, the paper industry continues its consolidation trend, which is carrying over into the speciality business. Disruptive technologies Foam forming Foam forming is a multi-phase fluid system structured by the presence of gas bubbles separated by thin liquid films. The bubbles impart increased sheet bulk and porosity to the paper. As the process has undergone a series of recent technical refinements, new systems employing foam forming are now entering commercial production for specialty paper types. A key focus is maintaining sheet strength while not compromising the enhanced paper bulk; one process is employing cellulose nanofibrils (CNF) to give a reported 16-19 percent improvement in tensile strength. The first product to come from the 21st century foam forming development is Paptic’s extensible paper bag stock, which offers a more environmentally friendly substitute for plastic. Precision in papermaking In practice, this means lighter paper grades from high-precision machines can compete with the same performance as heavier weight papers from less precise machines. Simultaneously, superior coater designs are facilitating quick changes of coating formulations between grades with little time or material waste. Improved product quality and costs will allow increased penetration of speciality paper grades into new applications and markets. A more disruptive impact will be the implementation of precision technology on faster and wider papermaking machines, allowing them to compete in the speciality spaces that have hitherto relied on slower, labor-intensive papermaking. Industry 4.0 While computers have been used on paper machines since the 1960s, new systems are integrating technical processes, quality systems and supply chain management in automated harmonized systems that reduce cost, and will allow larger production lines to behave like the small, nimble producers of the past. In combination with new online sensors for real-time monitoring of product attributes, these will enable owners of larger and wider machines to deliver the precision required in many specialty grades. A fine example of this trend is the evolution of headboxes with online CD basis-weight profiling. The headbox slice is kept as straight as possible, but the excess weight in a small area is corrected by injecting water in narrow segments to displace just the excess fiber. This is finally a robust control system for headbox fiber weight distribution. It matches the precision of the new high-resolution sheet scanner systems, correcting fiber weight differences in the cross direction of the tissue sheet. Stretchable papers Stretchable papers are a new concept intended to replace plastics with natural paper webs, aligning with brand desires for a more sustainable persona, especially for single-use packaging. They can be supplied in reels that can be printed, coated and otherwise processed on traditional converting lines previously used for polymers. The key end products include tray-format packaging and pharmaceutical blisters for stiffness and advertising, paper cups and other liquid containers, and decorative foils for furniture. The impact of these exciting technologies and other key market trends is discussed in detail in The Future of Speciality Papers to 2022 , published earlier this year by Smithers Pira.

For a modest investment of $174, receive more than US$ 1000 in benefits in return. |

|||||||

|

||||||||

Regional market shares for specialty papers (by tonnage, 2017).

Regional market shares for specialty papers (by tonnage, 2017).