| |

· www.tappi.org

· www.tappi.org

· Subscribe

to Ahead of the Curve

· Newsletters

· Ahead

of the Curve archived issues

· Contact

the Editor

|

|

|

|

Europe Aims for 74 Percent Paper Recycling

The success of TAPPI's annual PaperCon event is largely due to the working professionals who plan the technical program. These volunteer leaders rely on their industry experience to create a program that actively addresses the critical issues attendees face on their jobs every day. We're pleased to offer a series of interviews with these leaders, to bring their expertise to a wider audience through Ahead of the Curve.

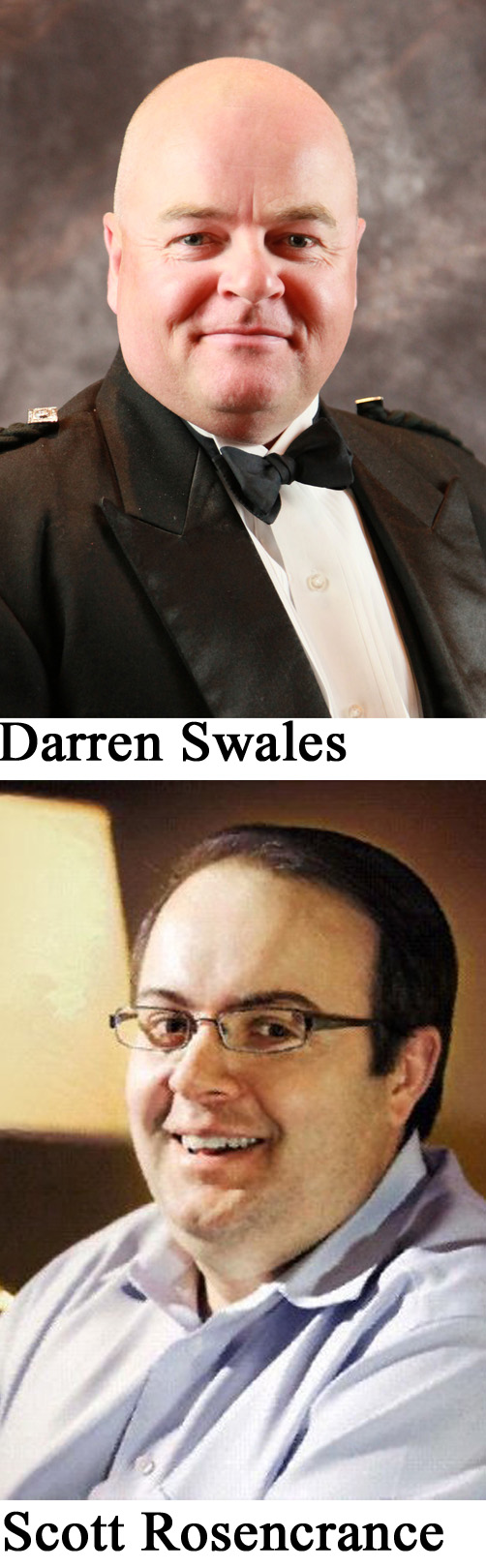

Scott Rosencrance is Senior Manager, Kemira, and Papermaking Additives Committee Chair 2019. He serves as the head of Kemira's marketing and applications team for defoamer and pulping additives, and has been in the pulp and paper industry for 25 years.

Darren Swales is Director of Business Development and Applications Group, Kemira Pulp and Paper Americas, and TAPPI Paper and Board Division Chair. He has 28 years of experience in the paper industry, originally in England; he moved to the United States in 1996.

TAPPI: What have been some of the greatest challenges you have each faced in your position and what resources did you use to overcome those challenges?

Rosencrance: What comes to my mind first and most clearly is the tremendous value in relationships. There obviously is a tremendous amount of information available in today's world but ultimately, knowing people who are experts—and having extensive personal experience available and accessible, people to talk to, often in real-time—is critical. The opportunity to discuss what they have done right, and what they could have done better, is a very valuable tool. I find TAPPI and TAPPI conferences provide a very good format for pulling together many of these real-life, tangible discussions and interactions that complement what we might read in the literature. The relationship side, and the tangible benefit of discussing these topics, is invaluable and a very common part of interactions at PaperCon.

Swales: It is ultimately the network—but before that network is built, it's the mentor who introduces you to the industry and the organization. I can still go back to my research professor, Michael Jaycock, who was the guy who got me involved in this industry when I was back in England. That introduction is critical; from there, it literally is like the germination of a seed, you need to tend it and work at it and then that network just starts building and it grows, year over year over year.

I think the challenge for most of us who are in the mid- to senior-level of our careers and lives is to relate to the younger professionals. I find it ironic that one resource I turn to is my children. My eldest is eighteen, so she's a good sounding board regarding what young professionals are wanting and expecting, and how to interact.

Both younger professionals and seasoned veterans come to PaperCon to get the basics. But others come to hear the latest trends—what's available for those interested in cutting-edge technology?

Rosencrance: One area getting a lot of traction in the industry is the physics in chemistry around additive mixing and the efficiencies of the additives.

Swales: One thing that has been exciting as PaperCon has progressed over the years is the format in which a session starts off with a tutorial bench as the introduction, followed by a subsequent set of papers—great for introducing new technologies.

This year we will have a little mix of everything. Also, for the first time, this year the Paper Physics Committee has joined the Paper Additives Committee in designing the track, so there is a real blend of basic theory and fundamentals into the more cutting-edge application mixing technology and chemistries. It's a good blend and it's always developing that way. That's what's good about PaperCon.

Combined, both of you have quite a few years of experience. What are some different trends you have seen over the years and what do you feel are the most critical issues facing the paper industry today?

Swales: I go back far enough that I still remember some alkaline conversions, which should be familiar to the more seasoned members of TAPPI. That was a huge fundamental change. Leaping forward, I think some exciting things these days are what we're seeing on the manufacturing side of repositioning assets. Unfortunately, newsprint and publication grades have taken a downturn but people have actually been repurposing those assets to get into the packaging segment. Great utilization—but there are some challenges, which is where the engineering and chemistry can help. It is good to see that that is progressing. It is also exciting that, in North America, we're actually seeing some new machines being built these days—again, in the growth segments, predominately packaging but also tissue and towel.

Rosencrance: Along those lines I notice a couple of dynamics. The industry as a whole has certainly seen a time of growth in tissue, towel, and packaging grades. At the intersection of that growth I see three themes, if you will, coming into play. One element is sustainability, which is both forward-looking and present-looking. In addition, there are process efficiencies and functional efficiencies of the various additives that are introduced in the paper process. When you put sustainability in the context of the efficiency and effectiveness of those various process and functional additives, it's an exciting time for our industry. We can see several new technologies as well as "re-optimized" existing technologies also emerging.

Are any of these trends being addressed at Papercon?

Rosencrance: In our Paper Additives track, attendees will find elements of all those themes in almost every session.

Swales: Volunteers were actually building the technical content in December. Several of us have worked together for a long time, and there are also people new this year. We are familiar with what's needed. Obviously, it's a jigsaw puzzle and you don't know what's going to happen; a lot of pieces come in through the abstract submissions process, and then the magic happens when that track is put together. We negotiate, we move things around—we try to make sure everyone who attends PaperCon gets an answer to a question they brought. And that's usually what happens.

Can you tell us more about the Paper Additives track?

Rosencrance: The responsibility of the Paper Additives Committee is to oversee the content of the track for the upcoming PaperCon. As in previous years, there will be a lot of conventional technical content. These traditional subjects will include sessions on dry strength new technologies—both natural and synthetic—as well as wet strength technology, which we've had in the past.

Additionally, there will be new sessions that focus on some of the new filler composites and their interaction with other materials. We will also have a diverse session focused on films and coatings this year. All in all, it will be a diverse, full session.

What do you feel mills need to do today to remain competitive in the future?

Rosencrance: Interestingly enough, in many ways my previous answer speaks to that: it's about the whole theme of sustainability, plus hitting the target grades and their growth. It's about finding innovative, new ways to not only apply those additives, but also to get the most out of their efficiency, whether they be process or functional additives.

Swales: One topic we've been covering more closely for mills over the last few years is data and analytics. The computing power and the knowledge of individuals driving that technology has increased dramatically. Making sense of that data and being able to predict the future better for the grade or the machine is paramount, which ties in to the sustainability theme that Scott highlighted. We've touched on that in the past and we're doing it now.

Your team has attended PaperCon in the past. How has PaperCon helped you and your company achieve goals?

Rosencrance: Relationships and the network we create year after year are critical. The content, of course, is new and interesting every year. So, every year you'll find multiple papers that are on new subjects that have just surfaced. This year we have the Papermaking Fundamentals Track for the first time really emerging in its own way. There is an enormous amount of new content this year that will speak on these fundamental topics. These fundamental efforts are a foundation upon which some of the practical applications and optimizations eventually come into use in our industry.

Sometimes these advances don't become evident for several years. However, history shows that if we look at the forefront of research we will see these fundamentals stimulating and contributing advances in technology. At this year's PaperCon, you're going to see a strong dose of content centered on the fundamentals.

Swales: What I find interesting is that, in our industry, for both suppliers and manufacturers, it's always safety first. Within TAPPI and PaperCon, it's always safety and antitrust first. So even though you have manufacturers, suppliers, and competitors in the same space, the Antitrust Policy is so upfront that, over years of networking, even competitors become friends and there's often a lot of exchange within career paths. PaperCon draws cutting edge technical content, and an impressive exhibitor space from global participants, making it the premier North American industry conference.

Why do you feel mills and other paper professionals need to attend PaperCon 2019?

Rosencrance: For those that have been there, the answer is clear: if attendance at PaperCon is at all feasible, fits their schedules, and is within their corporate budgets, they will be there. For those that haven't been there, it's difficult to put into words. What I would challenge them to do is to try it. Come to PaperCon once, then make your own determination based on your experience. We're pretty confident that after having been there, you will come back next year.

Swales: When you have almost 2,000 industry professionals gathered in the same place, you can find people to answer your questions. I agree, you've got to do it one time if you've never been and you'll be back.

What one word would you would use to describe PaperCon?

Rosencrance: Refreshing.

Swales: Awesome.

EARLY-BIRD REGISTRATION ENDS FRIDAY, APRIL 5. Also, learn about our special offer for mills—for a single fee, anyone on your mill team can attend for an hour, a day, or the entire conference and take advantage of the topics related to their job! Complete information at papercon.org.

For a modest investment of $174, receive more than US$ 1000 in benefits in return.

Visit www.tappi.org/join for more details. |

|