Efficient Production of Bio-Based Ingredients

Efficient Production of Bio-Based Ingredients

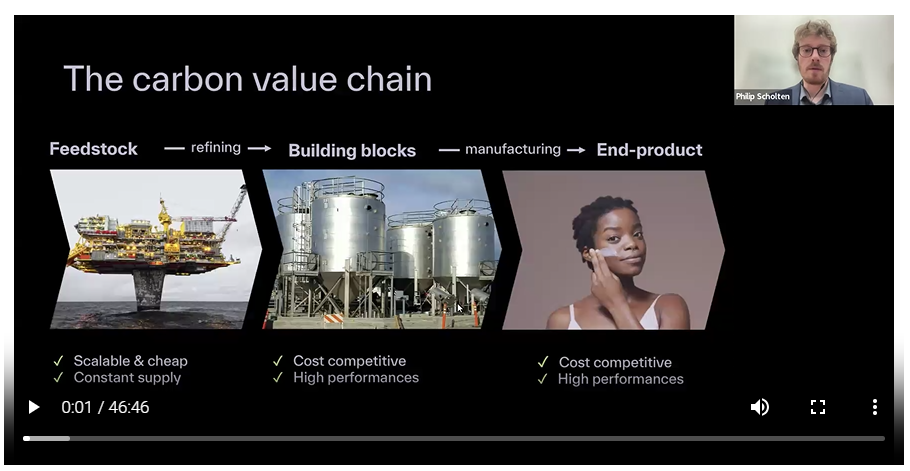

Biomass has been long deemed a ubiquitous resource for the chemical industry. However, extraction of bio-based chemicals and materials from biomass has struggled to compete with the efficiency, cost, and performance of the petroleum industry. Aldehyde-assisted fractionation (AAF) is an organosolv technique which enables to valorise all biopolymers present in biomass, namely lignin, hemicellulose, and cellulose, while maintaining a close control over the chemical integrity and structure of these bio-based structures. This precise chemical definition allows to attain performances which exceed fossil fuel analogues in high value applications, such as specialty chemicals or flavours and fragrances, and commodity applications, such as isolation foams and bioplastics. This seminar will highlight the key benefits of an AAF biorefinery with respect to performance while keeping a focus on sustainability metrics of the proposed bio-based alternatives.

Who Should Watch?

Job Titles

- Scientist

- PhD Student

Company

- R&D Organization or RTO

- University

Learning Outcomes

- Recognize different types of biopolymers and that the ways these are isolated from nature have a profound effect on their properties

- Distinguish between classical biomass valorisation schemes and lignin-first/holistic approaches

- Explain the relationship between chemical processes, their efficiencies, and their cost point

- Justify the use of bio-based chemicals and materials as a sustainable alternative for everyday applications

Speaker: Philip B. V. Scholten, Bloom Biorenewables

Philip B. V. Scholten holds a PhD in chemistry and has more than eight years of experience in research and development of renewable and sustainable polymers and chemicals. At Bloom Biorenewables he is currently the Chief Innovation Officer where he and his team develop sustainable biomaterials of the future. He is also the scientific communication officer of Circul-a-bility, a network of European scientists developing tomorrow’s circular food packaging, and an ally and advocate for equal opportunities and diversity in science. Outside of work Philip enjoys the outdoors and is a cooking and chocolate afficionado.

Philip B. V. Scholten holds a PhD in chemistry and has more than eight years of experience in research and development of renewable and sustainable polymers and chemicals. At Bloom Biorenewables he is currently the Chief Innovation Officer where he and his team develop sustainable biomaterials of the future. He is also the scientific communication officer of Circul-a-bility, a network of European scientists developing tomorrow’s circular food packaging, and an ally and advocate for equal opportunities and diversity in science. Outside of work Philip enjoys the outdoors and is a cooking and chocolate afficionado.